"You'll Never Walk Alone"

Sunday, June 22, 2025

Thursday, May 22, 2025

Tuesday, June 20, 2023

Electrical System.

ALTERNATOR

AMMO FUSE BOX

BATTERY ISOLATOR SWITCHES

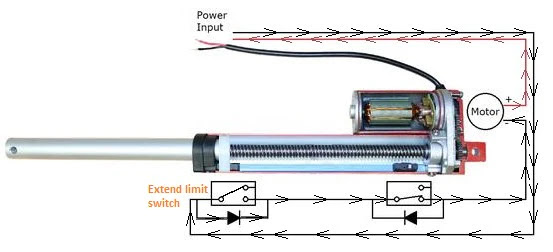

BUG CATCHER OPENER

EJECTION SEAT

COMPRESSOR

FUEL GAUGE

HEADLAMPS

PUSH START BUTTON

SPOT LIGHTS

STARTER MOTOR

STEERING WHEEL

SUPERCHARGER

Thursday, December 5, 2019

Ejection Seat

The Concept.

What is an Ejection Seat?

Once clear of the aircraft, the ejection seat deploys a parachute

Zero-Zero ejection seat -

Now this is what we want!

A zero-zero ejection seat is designed to safely extract upward and land its occupant from a grounded stationary position (i.e., zero altitude and zero airspeed), specifically from aircraft cockpits.

The zero-zero capability was developed to help aircrews escape upward from unrecoverable emergencies during low-altitude and/or low-speed flight, as well as ground mishaps.

Parachutes require a minimum altitude for opening, to give time for deceleration to a safe landing speed. Thus, prior to the introduction of zero-zero capability, ejections could only be performed above minimum altitudes and air-speeds. If the seat was to work from zero (aircraft) altitude, the seat would have to lift itself to a sufficient altitude.

The zero-zero capability was developed to help aircrews escape upward from unrecoverable emergencies during low-altitude and/or low-speed flight, as well as ground mishaps.

Parachutes require a minimum altitude for opening, to give time for deceleration to a safe landing speed. Thus, prior to the introduction of zero-zero capability, ejections could only be performed above minimum altitudes and air-speeds. If the seat was to work from zero (aircraft) altitude, the seat would have to lift itself to a sufficient altitude.

Zero-zero technology uses small rockets to propel the seat upward to an adequate altitude and a small explosive charge to open the parachute canopy quickly for a successful parachute descent, so that proper deployment of the parachute no longer relies on airspeed and altitude.

The seat cannon clears the seat from the aircraft, then the under-seat rocket pack fires to lift the seat to altitude. As the rockets fire for longer than the cannon, they do not require the same high forces. Zero-zero rocket seats also reduced forces on the pilot during any ejection, reducing injuries and spinal compression.

- A rescue seat for the Driver / Pilot.

- As this is a ground operated vehicle, it needs to be a 'Zero - Zero" type seat.

- This will require the seat to be rocket powered to 'clear' and 'deploy'.

- A parachute to land the seat and Driver safely.

- "End of Life" or "Terminate Mission" protocol for the safety of bystanders.

- "Dead Stop" - Integration to all systems after seat deployment - this is to ensure the safety of all at ground zero.

Further Resources needed:

- Rocket technology - to propel the seat 30 m into the air.

- Air Bag deployment technology - split second response timing.

- Altitude monitoring technology - to deploy parachute at precise moment.

- PD technology - Parachute Deployment by means of an explosive charge.

- HMD - Helmet mounted display for driver.

- Safety Harness / Neck Support / Quick Release System - Seat Evacuation Hardware - SEH

Wednesday, November 14, 2018

Friday, March 23, 2018

Hybrid Engine Drive Technology.

Read the complete article here.

https://hybridzigzag.blogspot.com.au/2017/12/final-drive-transmission.html

Subscribe to:

Comments (Atom)

.jpg)

.JPG)